Non Destructive Testing

[su_spoiler title=”TEMPO device” open=”yes” style=”simple” icon=”arrow”]

[su_column size=”1/3″]

[/su_column]

[su_column size=”2/3″]

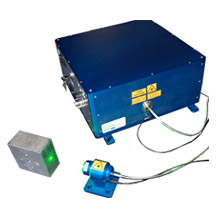

Thanks to Sound and Bright innovative approach, it is now possible to measure sub-picometer in-plane and out-of-plane displacement at high frequency (up to 1 GHz) on any surface type without contact. Based on photorefractive two-wave mixing, TEMPO works at optimum performances with the multi-speckled beam. TEMPO large aperture (2″ ~ 50mm) collects much more optical power on diffusing surfaces than a classical interferometer, which directly translates into higher sensitivity and signal to noise ratio. TEMPO output delivers a time signal directly proportional to the surface displacement of the sample.

TEMPO comes with various options adapted to customer needs and applications.

- Select the optimal detection bandwidth from 10MHz, up to 1 GHz.

- Choose the right spot size on the sample for your application, ranging from 10 microns for high precision, to more than 100 microns.

- Upgrade your measurement to simultaneous in-plane and out-of-plane displacement.

- Adapt the output laser power to your sample reflectivity, from 150 mW to 500 mW for an internal laser, up to more than 5W for an external laser.

- Optimize the optical stand-off of the detection, up to 500 mm.

Designed for point and shoot operation, TEMPO is easy to operate (calibrated output, focus controlled by USB connection, an internal photodiode for the trigger, etc.) and can be coupled to a 2D scanner (X-Y or angular) for full-field analysis.

TEMPO is used in numerous Universities and private R&D laboratories for materials research and wave propagation studies.

[wpdm_package id=’372′]

[wpdm_package id=’374′]

Find more about TEMPO: here.

[/su_column]

[/su_spoiler]

[su_spoiler title=”QUARTET device” open=”yes” style=”simple” icon=”arrow”]

[su_column size=”1/3″]

[/su_column]

[su_column size=”2/3″]

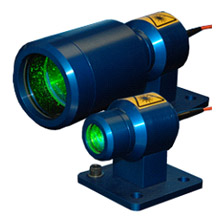

Sound and Bright is pleased to introduce QUARTET, a cost-effective interferometer based on multi-channel random quadrature detection technology.

QUARTET is designed for remote detection of sub-nanometer displacements (Patent # 2005/062941 A2). No path stabilization is required. The stability of the interferometer is based on the multi-channel, parallel demodulation that is done electronically. Quadrature interferometers have been used for more than 20 years for detection of small surface motions. The performance of these interferometers was initially limited by the quality of electronic components that were available (limited bandwidth & dynamic). With the recent improvement of electronic components, quadrature interferometers have now reached maturity, exhibiting high-bandwidth and high sensitivity. QUARTET uses an innovative „random quadrature” demodulation scheme that takes advantage of the random phase distribution inherent to speckle light. High sensitivity is achieved through multi-channel detection and parallel processing. The detectors produce a time-varying analogue voltage that is proportional to the rectified instantaneous surface displacement at ultrasonic frequencies. Sound and Bright proprietary multi-detection system increase the effective collection efficiency (the increase of sensitivity & reduction of signal dropout caused by speckles) without reducing the depth-of-field.

[wpdm_package id=’378′]

Find more about QUARTET: here.

[/su_column]

[/su_spoiler]

[su_spoiler title=”QUARTET LTG device” open=”yes” style=”simple” icon=”arrow”]

[su_column size=”1/3″]

[/su_column]

[su_column size=”2/3″]

Spund and Bright developed a remote and turnkey system for thickness measurement of materials: Quartet Laser Thickness Gauge. The system is composed of 1) QUARTET receiver with an internal laser (l=532nm): detection bandwidth [1MHz – 20MHz] 2) Generation laser: NdYag pulsed laser (l=1064nm), 100mJ per pulse (10ns pulse duration) with repetition rate 20Hz 3) Acquisition card and computer for data acquisition and display. This Laser Thickness Gauge (LTG) is based on our ultrasonic receiver QUARTET. The receiver is laser-based, and benefits from a highly sensitive, robust, non-contact, remote and non-destructive inspection technique. The laser head can easily be implemented on a supply chain. Typical thickness measurement accuracy is better than 10µm.

[wpdm_package id=’381′]

[/su_column]

[/su_spoiler]

back